Stick Pack details and options

Forming shoulder

The film is split into the appropriate witch strips.

The film strips then go over the forming shoulder and into the forming tube area.

The film strips then form a tube shape leaving the two edges protruding in a 'lapped fin' configuration.

The photo shows a forming set on a 3 lane liquid stick pack machine.

Vertical Sealing Jaws

The film tubes are then forced down the forming tube and are presented to the vertical sealing jaws.

The sealing jaws close thus forming the vertical seal.

The vertical sealing jaws are temperature controlled and the dwell time adjustable enabling the stick seal integrity to be optimized.

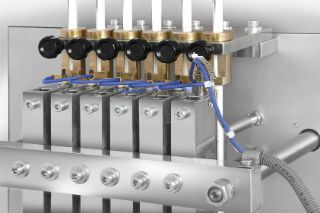

Photo shows the vertical sealing jaw set on a 6 lane granule machine

Filler/pump system

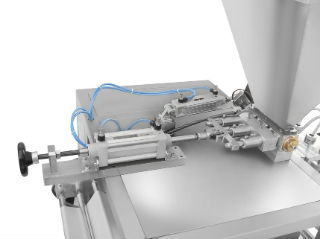

Photo shows a piston pump/filler with rotary valve technology for filling, liquids, pastes & gels. This photo shows a 3 lane gel system.

All metallic product contact parts are manufactured from stainless steel.

Micro adjustment of the dose volume/weights can be adjusted when the machine is in operation or when it is static for optimum flexibility.

Discharge Conveyor

Once the stick pack is complete and the is discharged, a takeaway conveyor can be used to take sticks on to the next process in the overall process.

The standard conveyor is slightly inclined to present the sticks at waist height for manual bulk packaging.

Alternate configurations can be offered including counter controlled flap mechanisms to automate bulk packaging.

Photo shows standard take away conveyor.